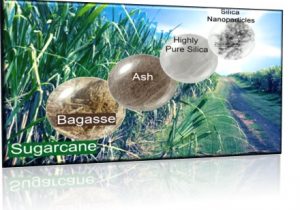

The Indian cane sugar industry uses bagasse as a fuel in boilers wherein significant quantities of fly ash is generated as waste. This fly ash while is of no commercial value at present, also creates environmental issues. Bagasse fly ash which is Si-rich, can be a potential resource to produce silica-based high-value products, such as silica nanoparticles (SiNPs) said Prof. Narendra Mohan, Former Director, National Sugar Institute, Kanpur.

Silica nanoparticles play an important role in medical imaging, diagnostic and therapeutic bio-analysis, membranes for fuel cells, Li-ion batteries, adsorbents, catalysis and crop improvement etc. Adding value to agro-industrial, the development of nano-silica has appeared as promising agent for the plant growth, fertilizers and pesticides.

During sugarcane crushing of the order of about 300 MMT, the bagasse production is likely to be about 90 MMT during the season 2024-25, major part of which is to be used as fuel in boilers. Innovative and creative ways to reduce waste and the contamination of the environment, minimizing environmental impacts have been targeted in 21st century. The largest agro-industrial by-products of the world are rice husk and straw, corn cobs, wheat straw and sugarcane bagasse. Among these by-products, sugarcane bagasse, rice husk and straw can be highlighted because of their silicon content, being important renewable sources.

As we know, bagasse at present is majorly used as fuel and steam through boiler and only a limited amount is utilized for other purposes i.e. paper, tableware production etc. For making Indian sugar industry self-sustainable, there is stress on converting sugar factories into bio-refineries producing bio-chemicals, bio-products and bio-energy. Presently sugarcane bagasse fly ash (SBFA) obtained during the combustion process of the sugarcane bagasse is used mainly as landfill.

A new Green synthetic method for silica nanoparticles using sugarcane bagasse fly ash (SBFA) as the silica source and HCTAB as the surfactant via sol-gel technique in water/butanol was developed by Ms. Shalini Kumari under my supervision and silica nanoparticles were successfully synthesized from the sugarcane bagasse fly ash. The structural properties of SiNPs were analyzed using different standard techniques, viz. Scanning Electron Spectroscopy, X-Ray Diffraction Analysis and Fourier Transform Infrared Spectroscopy. This has led to the development of technology for low-cost production of silica nanoparticles for various practical applications and provides way to solve problem of fly ash pollution in the sugar industries with the development of a value- added products said Prof. Mohan.

If you want to read more about the news about the Sugar Industry, please continue reading Chinimandi.com