Insight Focus

- Domestic sugar prices in Maharashtra have strengthened in the past week.

- Raw sugar imports are still not viable.

- Rumours suggest ethanol diversion could fall as low as 3m tonnes.

Introduction

India, the world’s second-largest producer of sugar, aims blend 20% ethanol in gasoline by 2025.

This ethanol will be derived from sugar cane and various grain feedstocks, offering Indian mills the flexibility to choose how they utilize the sucrose in the cane. We will show the choices they are making in this report.

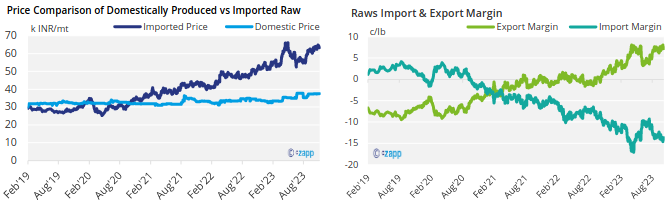

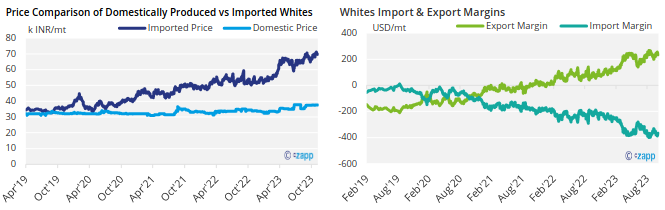

Maharashtra Sugar Imports/Exports

Domestic sugar prices in Maharashtra have risen to 37.5INR/kg in the last week. However, with global sugar prices at 12-year highs, mills could earn a large margin over domestic sales if they were allowed to export this season.

Imports of raw sugar are still not viable and would only be feasible at a local sugar price of INR 63.3/kg. The government won’t allow prices to rise this high given the general election in May 2024.

The story is similar for white sugar – mills could theoretically earn a higher margin over domestic sales if an export quota was set for the season.

Ethanol vs Sugar

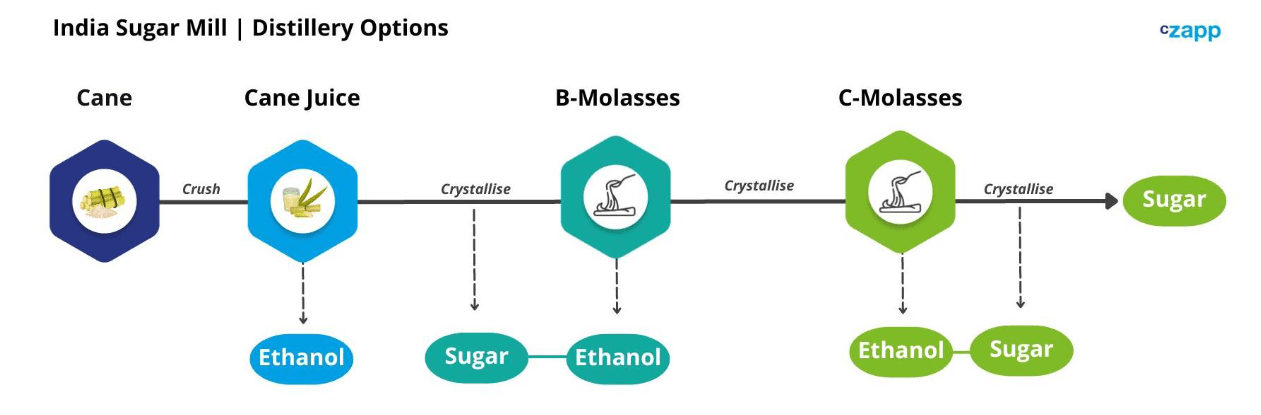

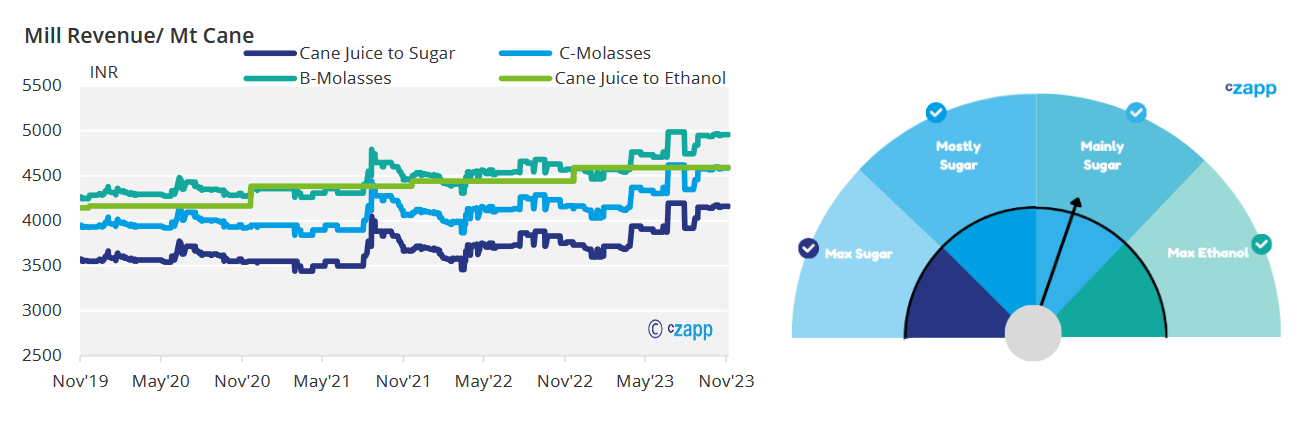

Many mills/distilleries have a choice over which feedstocks they use to make sugar or ethanol based on the relative prices of ethanol paid by the oil marketing companies.

At today’s prices, processors are most likely to choose to make ethanol from B molasses, which yields mainly sugar.

This means that 4-5m tonnes of Indian sucrose should be diverted to make ethanol, though there have been rumours that this figure could fall as low as 3m tonnes.

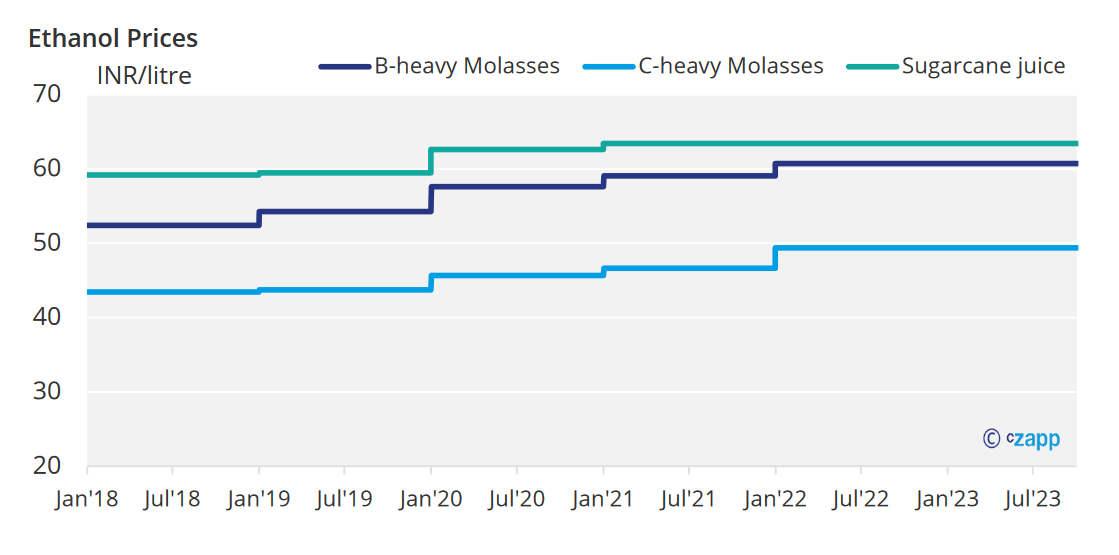

Given the poor outlook for this year’s cane crop, the government can change the ethanol prices paid to incentivize mills to use C-molasses or cane juice exclusively for sugar production, thereby reducing ethanol diversion. Here are the current feedstock prices for ethanol:

For more articles, insight and price information on all things related related to food and beverages visit Czapp.

For more articles, insight and price information on all things related related to food and beverages visit Czapp.